Mold Design Control

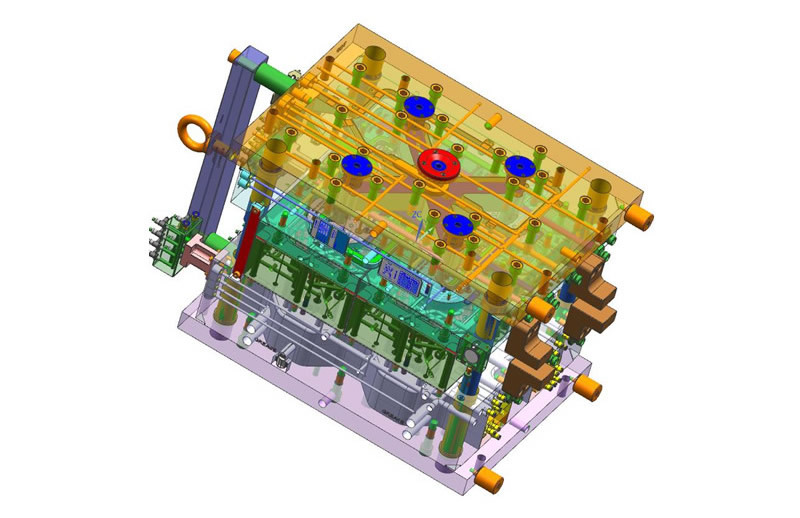

<p>During DFM stage, we will study the part design carefully and come up with the optimal solutions if there is any issue that affects the tool function.</p>

<p>During mould design stage, we will first go through customer mould standards and make sure the tool design fully meets customer's requirements.

</p>

<p>We focus specially on cooling, air venting, welding line, deformation control, etc., in order to make the tool with optimal design.

</p>

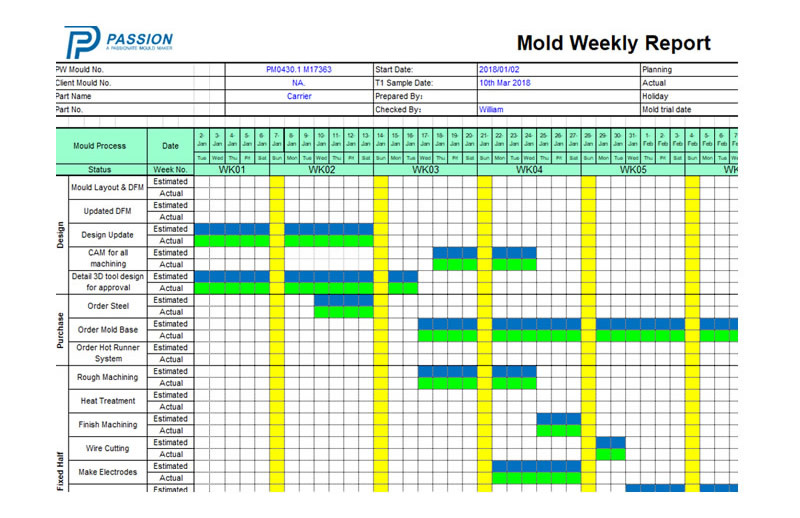

Weekly Construction Plan

Once mould design is approved, a detailed construction plan will be provided, which indicates The T1 test and will be updated every week.In case of any change of the plan, solutions will be provided in advance immediately.

Pre-T1 Inspection

For each component, it will be checked after each machining work is done, to guarantee the correct dimensions are matched.

Before T1 test, we will fit and check all the components in the tool, to find any potential risks of defected parts.

T1 Test

<p>During T1 test, we will provide T1 test report with pictures, T1 samples inspection report, T1 test video and send the required samples to customer for inspection.

</p>

<p>

Any issues on the samples will be reflected in the test report and a solution will be provided.

</p>

Tool Improvement

After get samples feedback from customer, we will check and provide a complete tool improvement plan, including detailed work method and lead time, and next trial date will also be informed.

Tool Shipment

We can provide various methods of shipment: sea/air/express/train, under different intercoms. Based on customer request, we can handle each shipment from tool pick-up to tool delivery.