About Passion

Passion Mould is a complete manufacturing facility specializing in design, mould making and injection moulding. We always focus on offering customized business solutions at the highest standard.

Factory floor space

Number of staff

Annual output tool

Products

Service

Design Service

Tooling

Injection Molding

Secondary Operation

Silicone Rubber Molding

Secondary Operation1

Design Service

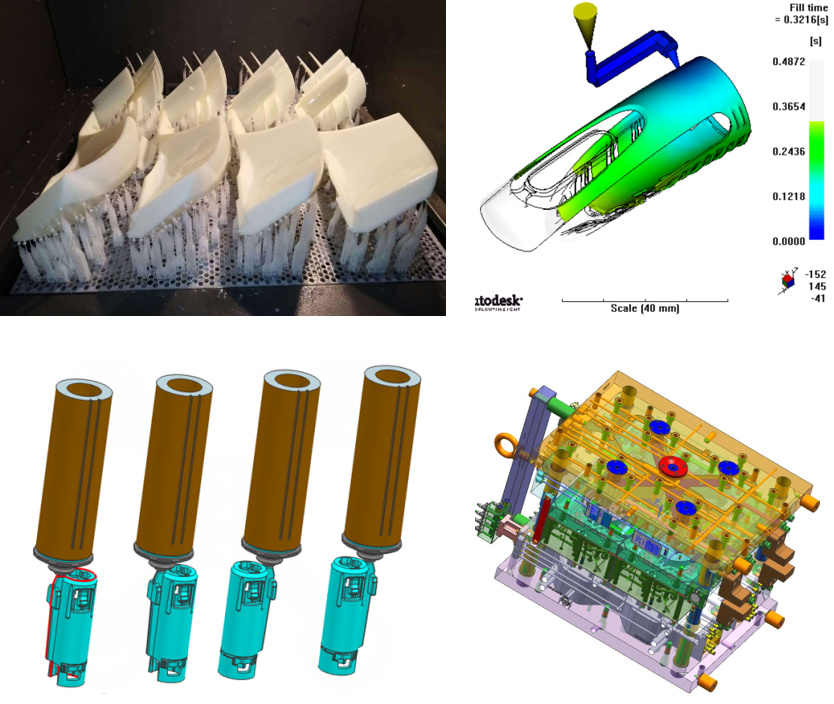

3D Printing

DFM Analysis

Mould Flow Analysis

2D & 3D Mould Design

Rapid Prototype (SLA & SLS)

Tooling

Prototype Mould

Insert Mould

Over Mould

2K Mould

Multi-cavity Mould (Up to 96 cavity)

Silicone Rubber Mold

Injection Molding

Injection Mold Trial

Low Volume Production

High Volume Production

Secondary Operation

CNC Machining

Product Assembly

Ultrasonic Welding

Pad Printing & Silk Printing

Silicone Rubber Molding

Custom silicone molding services:

Solid Silicone Rubber Molding (HCR),

compression molding

Liquid Silicone Rubber Molding (LSR)

Secondary Operation1

Project Management

With a professional project management team, Passion Mould is able to provide our customer a highly efficient management service from the design stage till tool shipment, including after-sales maintenance.

Mold Design Control

Mold Design Control

During DFM stage, we will study the part design carefully and come up with the optimal solutions if there is any issue that affects the tool function.

During mould design stage, we will first go through customer mould standards and make sure the tool design fully meets customer's requirements.

We focus specially on cooling, air venting, welding line, deformation control, etc., in order to make the tool with optimal design.

Weekly Construction Plan

Weekly Construction Plan

Pre-T1 Inspection

Pre-T1 Inspection

T1 Test

T1 Test

During T1 test, we will provide T1 test report with pictures, T1 samples inspection report, T1 test video and send the required samples to customer for inspection.

Any issues on the samples will be reflected in the test report and a solution will be provided.

Tool Improvement

Tool Improvement

Tool Shipment

Tool Shipment

News

28

2022-07

Passion Mould is a leading plastic injection mold and plastic product manufacturer

Passion Mould is a leading plastic injection mold and plastic product manufacturer. We have 2 plants of total 3,500 sq meters and 85 employees: one location focuses on small & medium-sized precision moulds and silicone rubber molds (HCR and LSR) while the other one focuses on large moulds.